Switch Gear and Automation

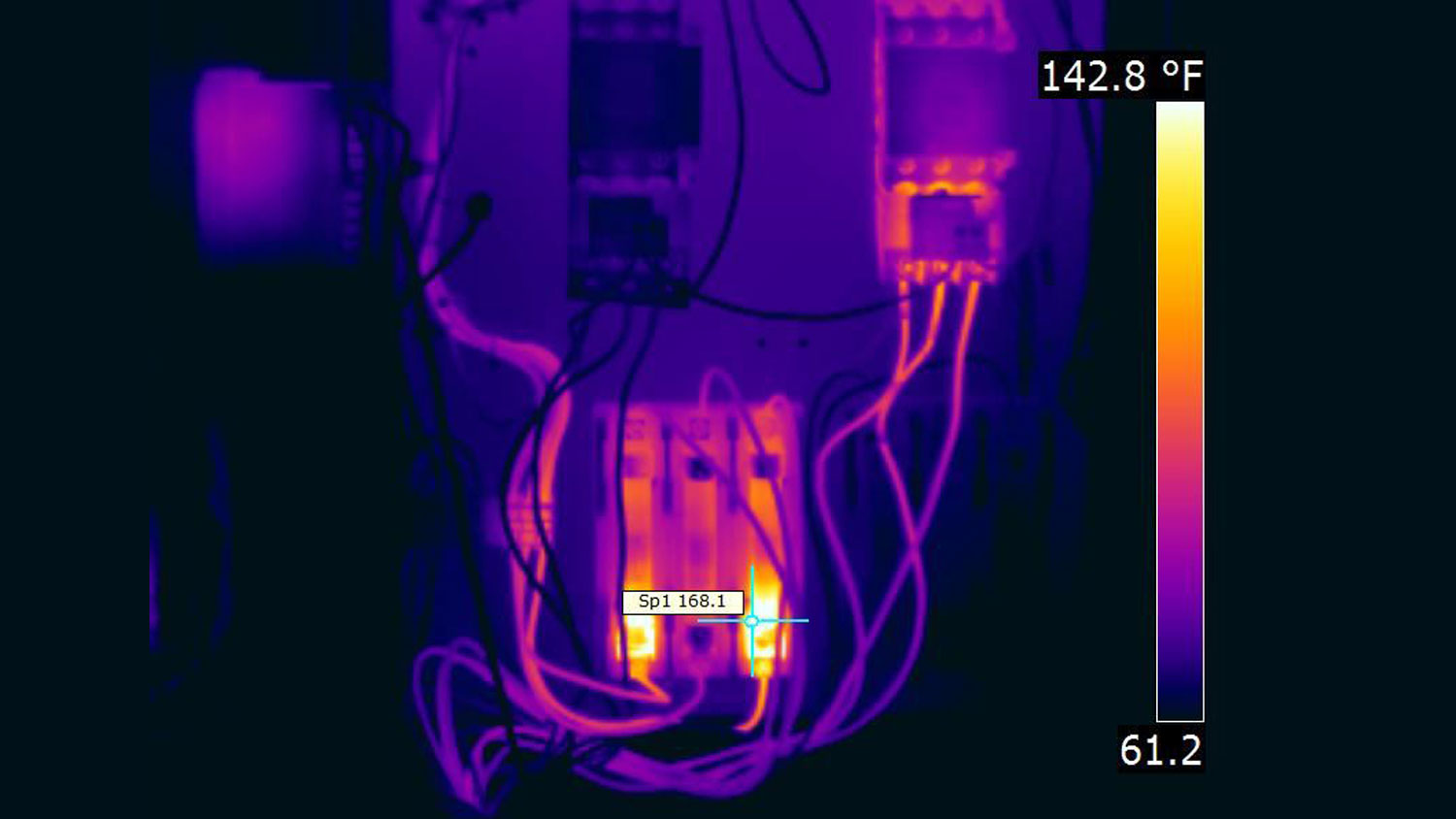

Switchgear and Thermography

Westside Electric’s expertise, paired with performing Infrared Scans or thermography, detects hot spots within switchgear. Hot spots cause undue wear and tear on components leading to downtime and safety issues. Thermography scans are conducted without interruption to production. After the facility scan is completed, a full report, including images, will be provided along with recommendations for repair or restoration or replacement of problems found. Westside Electric recommends a regular Infrared Scan to locate problem areas so that the problems can be fixed easily.

Automation

Westside Electric’s knowledge about controls and automation ensures that the biggest and most sensitive of systems is safely operational at all times. Both driver and variable frequency controls, manual or automated through PLC, Westside Electric can test, repair or replace them in a variety of industries.